Introduction to Filter Media

In filter press systems, filter media play a vital role in separating solids from liquids. High-quality media enhance performance, reduce downtime, and support long-term operation. Choosing the right type depends on the slurry type, desired clarity, and filtration speed.

What Is Filter Cloth?

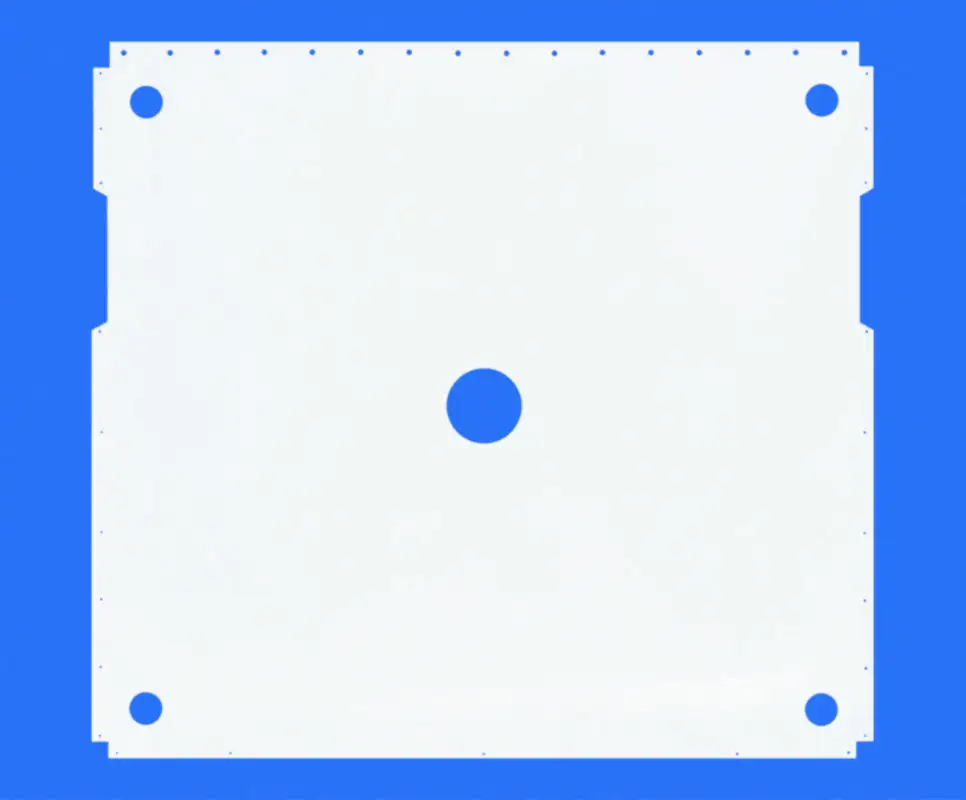

Filter cloth is the most common type of filter media. It’s placed between plates in a filter press and traps solids while letting clean liquid pass through. The Jingjin filter cloth is known for its durability, tight weave, and chemical resistance, making it suitable for a wide range of applications.

Types of Filter Cloth Materials

Here is a comparison of common filter cloth materials:

| Material | Features | Common Use |

|---|---|---|

| Polyester | Strong, cost-effective | General filtration tasks |

| Polypropylene | Acid and alkali resistance | Chemical industries |

| Nylon | High tensile strength | Sludge dewatering |

Why Jingjin Filter Cloth?

Jingjin filter cloth offers superior filtration precision and longer service life. Its design helps maintain consistent cake formation and flow rate. Operators prefer it for industries such as mining, food processing, and pharmaceuticals.

Filter Media Selection Tips

Choose filter cloth based on:

-

Slurry particle size

-

Chemical compatibility

-

Temperature conditions

-

Press type (chamber or membrane)

Always test compatibility before bulk use to avoid damage or loss in efficiency.

Conclusion

Using reliable Jingjin filter cloth ensures cleaner output and optimized filter press operation. Invest in quality media to extend system life and improve your plant’s efficiency.

Comments on “Fiilter Media and Filter Cloth for Filter Press Systems”